Cutting-edge innovation

We develop high-performing Fuel Cell technology to boost the performance and competitivity of our StackPack™ systems, thereby enabling the rapid and competitive development of clean hydrogen mobility.

A unique, holistic and integrated approach to develop solutions adapted to each application.

.png)

At Symbio, we master all the key components and performance criteria of our fuel cell systems:

- The electrochemical core (Membrane Electrode Assembly or MEA);

- The fuel cell formed by the stack of bipolar plates and MEAs;

- The system (Balance Of Plant, operating conditions, packaging).

This integrated mastery of our systems enables us to optimize each parameter. We are gradually developing new generations of integrated solutions that will further improve their technological performance. Coupled with cutting-edge industrialization and a progressive increase in volumes, these will enable us to boost the competitiveness of fuel cell technology and gradually reduce unit costs to match diesel solutions by 2030.

A proprietary and demanding methodology for performance measurement.

We have developed our own assessment grid for fuel cell system performance: ten criteria taking into account the essential dimensions of performance, to enable us to define the best solution for each application, optimizing total cost of ownership (TCO) throughout the vehicle life cycle, without oversizing or compromising on performance.

360° open innovation : unrivalled capabilities, concentrated in our world-class innovation center.

We have chosen to bring together all our Research & Innovation (R&I) teams at our new world-class industrial site, SymphonHy, Europe's biggest production site for fuel cell systems. Liaising directly with our production teams, it is designed to foster open innovation.

Our Research & Innovation teams include members from a range disciplines: design, chemistry, electrochemistry, physical chemistry, formulations, coating, polymer and metal materials, electrical engineering, mechatronics, systems, multiphysics simulation, command control, advanced quality control, physical measurement, etc.

Bringing together all our experts and researchers under the same roof encourages rapid iteration, co-construction and the emergence of new generations of fuel cells that are ever more disruptive, competitive and suitable for industrial production, meeting the needs of every type of mobility.

Our teams work in an R&I center of unprecedented scale for our industry, equipped with cutting-edge technology.

- An R&I center of unparalleled scale

- 100 engineers and 20 PhDs

- Around 20 nationalities

- Partnerships with world-renowned research laboratories

Lifecycle thinking: a systemic approach to reduce the environmental footprint of our solutions.

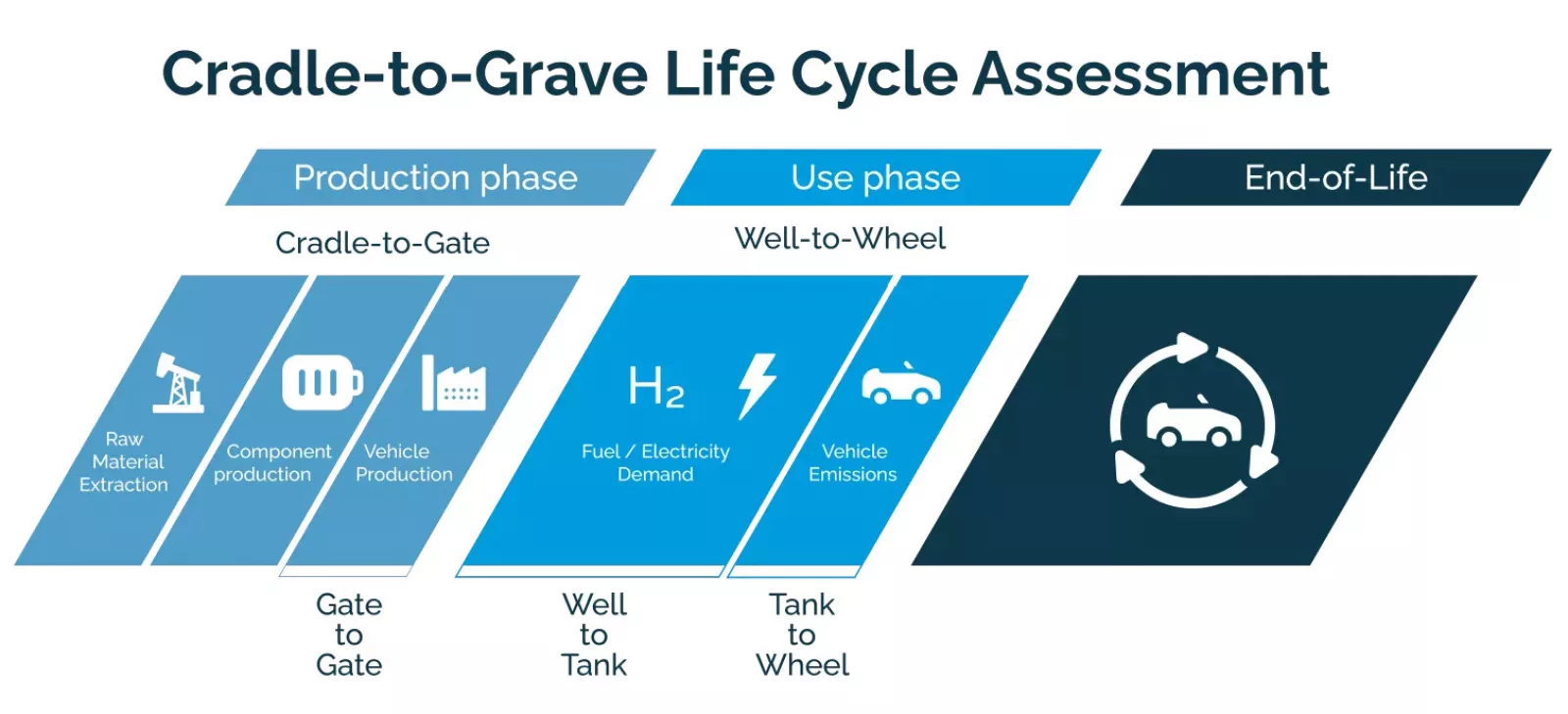

As the hydrogen industry is still in the process of being structured, there are currently no common standards for the environmental impact of our products. We are involved in several European initiatives (such as eGhost and SH2e) and are working to develop a method for analyzing the impact of our systems, coupled with recommendations for optimizing the cradle-to-grave environmental footprint.

Analyzing the life cycle of our fuel cells to minimize their environmental impact.

Based on the circular economy principle, we have developed a comprehensive and demanding methodology that compiles and evaluates all the inputs, outputs and potential environmental impacts of our fuel cell systems throughout their life cycle, from sourcing to end-of-life and any recycling operations. Our approach takes into account eco-design, waste reduction and recyclability, carbon footprint, water and air quality, biodiversity and raw materials sourcing.

Contributing to a responsible European hydrogen ecosystem.

Convinced of the power of collective intelligence, we exchange and collaborate with the world's leading laboratories. As a key player in fuel cell technology, we are committed to Europe-wide projects aimed at defining common measurement and analysis tools for our industry, to help it adopt a responsible and sustainable approach :

- The eGHOST project aims to set a first common milestone in eco-design criteria for the European hydrogen industry. The ultimate aim is to provide solid eco-design guidelines for fuel cell systems. Specific guidelines will be issued for two products: the proton-exchange membrane fuel cell (PEMFC) and the solid oxide electrolyzer (SOE). Find out more

- The SH2E project aims to develop common guidelines for the environmental, economic and social life cycle assessment of fuel cell systems through the establishment of a harmonized multidimensional framework for life cycle sustainability assessment and prospective analysis of fuel cell systems. Find out more

HyMotive: a transformational project that accelerates Symbio's roadmap to become a world-class fuel cell player.

SymphonHy is part of our seven-year, €1 billion investment plan through our HyMotive project, supported by the European Commission as part of the Hy2Tech wave of the IPCEI (important projects of common European interest) hydrogen program, and by the French Government (France 2030, France Relance).

It aims to accelerate Symbio's industrialization and disruptive innovation, and will lead to the creation of 1,000 jobs. It will contribute to the construction of a solid hydrogen ecosystem in Europe, a key lever for achieving Europe's net-zero target.

In its second phase, HyMotive will develop and industrialize a new generation of innovative fuel cell systems, based on disruptive technology. This will boost the performance of Symbio's StackPack™, while drastically reducing unit costs.